When it comes to designing an electronic product, one of the most crucial components to consider is the Printed Circuit Board (PCB). Whether you’re developing a simple consumer gadget or a complex industrial system, the PCB is the backbone that ensures all the components function together seamlessly. But did you know that your choice of Printed Circuit Board supplier can significantly impact the overall product design process? In this blog post, we’ll dive into how PCB suppliers influence your product design and why selecting the right one is crucial for the success of your project.

The Role of Printed Circuit Boards in Product Design

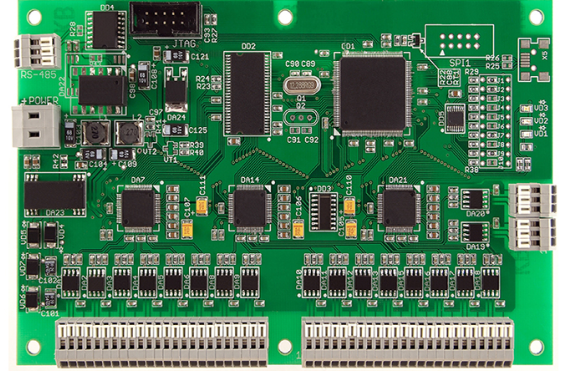

Printed Circuit Boards (PCBs) are essential to nearly every modern electronic device, providing both the physical structure and the electrical connections necessary to make the device function. The board connects various electronic components—such as microchips, resistors, capacitors, and connectors—through conductive paths etched onto a flat surface.

During the design phase of any electronic product, it’s crucial to ensure that the PCB meets the required specifications for size, functionality, durability, and performance. Whether your product is intended for consumer electronics, medical devices, automotive systems, or industrial machinery, the design and quality of the PCB play a pivotal role in the overall performance and reliability of the end product.

The Impact of PCB Suppliers on Product Design

The choice of Printed Circuit Board supplier can greatly influence your product design in several ways. Here’s a breakdown of the key areas where the supplier’s role matters:

Quality Control and Reliability

The quality of the PCB can directly affect the reliability and longevity of your product. A poorly made PCB could lead to product malfunctions, failures, or even safety hazards, especially in mission-critical applications like medical equipment or automotive electronics. A reputable PCB supplier will ensure that all boards meet the highest standards for quality and testing.

When working with a reliable supplier, they will provide certifications and offer detailed quality control processes, such as automated optical inspection (AOI), x-ray inspection, and functional testing to ensure that each PCB is defect-free. This process significantly reduces the risk of errors during the manufacturing stage and enhances the overall quality of the final product.

Customization and Design Support

Many projects require customized PCB designs that meet specific functionality requirements. The complexity of these designs can vary depending on the intended use of the product. A skilled Printed Circuit Board supplier will provide valuable assistance during the early stages of design, helping you translate your ideas into a practical, manufacturable solution.

Experienced PCB suppliers often offer design support services, such as design for manufacturability (DFM) checks, signal integrity analysis, and thermal management solutions. These services ensure that your product design is optimized for mass production, helping to avoid potential issues down the road. Moreover, they can help identify any design flaws that could lead to inefficiencies or malfunctions.

It’s essential to check over here for PCB suppliers who offer these types of advanced support, as it can be the difference between a successful product launch and costly delays or redesigns.

Time to Market and Production Efficiency

Product development timelines are often tight, and delays in PCB manufacturing can push back the entire project. Working with an experienced Printed Circuit Board supplier can help you streamline the manufacturing process and reduce lead times. Established suppliers typically have well-established processes and the necessary infrastructure to handle bulk orders efficiently and accurately.

Additionally, a reliable PCB supplier will provide you with accurate and up-to-date production timelines, helping you make informed decisions about the overall project timeline. By partnering with a supplier who can deliver quality products on time, you can stay on schedule and avoid costly delays in the production process.

Cost Management

PCB suppliers can have a direct impact on the cost-effectiveness of your product design. Opting for a low-cost supplier may seem like an attractive option, but if they compromise on quality, you may face costly failures or defects that could erode your profits in the long run. Conversely, premium suppliers often charge higher rates but provide greater reliability and value.

It’s essential to balance cost with quality when selecting your Printed Circuit Board supplier. An experienced supplier can help you optimize the design for cost savings, such as reducing the number of layers or choosing alternative materials, without sacrificing quality. They may also offer bulk discounts, which can significantly reduce production costs for large runs.

Always ask your supplier for an upfront quote and assess the overall cost relative to the value provided. A transparent, experienced supplier will work with you to keep costs manageable without compromising on performance.

Prototyping and Testing

Before you go into full-scale production, testing prototypes is a vital step in verifying the design and functionality of your product. A trustworthy PCB supplier will offer prototyping services to produce small batches of your design for testing and validation. This process helps identify any flaws early in the design stage, preventing costly mistakes during full production.

In addition, a supplier with a strong prototyping capability will allow you to conduct thorough testing of the PCB under real-world conditions, ensuring it meets all performance requirements. By making minor adjustments at the prototype stage, you can avoid significant redesigns later on and save time and money in the long run.

Supply Chain Stability

Another important aspect of working with the right Printed Circuit Board supplier is their supply chain stability. Global supply chain disruptions can delay production timelines and affect the availability of materials. A supplier with a robust, diversified supply chain is more likely to weather such disruptions and maintain consistent delivery times.

Additionally, a supplier with a global network can source the best materials from various regions, ensuring that you get high-quality components at competitive prices. They will also be more flexible in meeting your specific needs and adapting to any changes in the supply chain.

Conclusion

Your Printed Circuit Board supplier plays a crucial role in shaping the success of your product design. From ensuring high-quality manufacturing standards to offering design support and cost-effective solutions, the supplier you choose can directly influence your product’s performance, reliability, and time to market.

Selecting the right partner can be the difference between a seamless, efficient development process and costly delays and failures. Be sure to carefully evaluate your supplier’s capabilities, certifications, and reputation in the industry. By doing so, you’ll be well on your way to creating a successful, high-quality product that stands out in the market.