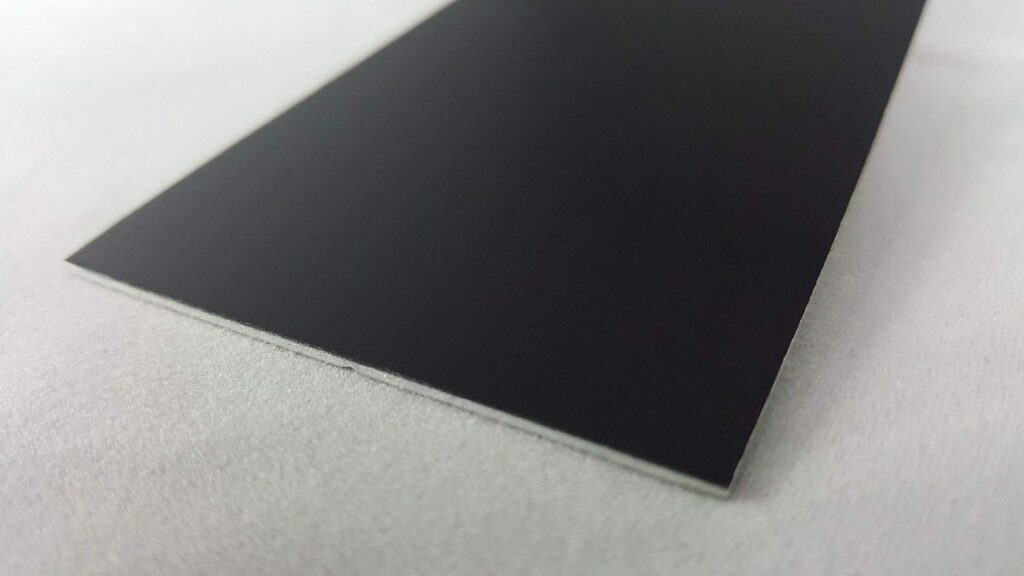

Black anodized aluminum stands out as a flexible alternative that blends exceptional functional advantages with visual appeal in today’s world of cutting-edge materials and sustainable design options. Ordinary aluminum is transformed into something unique by this specialist treatment process, resulting in a material that not only appears smart but also performs better in a wide range of applications. The black anodised aluminium has emerged as a popular option for designers and engineers looking for the ideal harmony between appearance and function in everything from consumer electronics to architecture. Let’s examine the unique benefits that this exceptional substance offers.

1.Enhanced Durability Against Everyday Challenges

Black anodized aluminum generates an extended material lifetime when used in challenging environments. Anodizing performs beyond surface treatment because it transforms aluminum skin into aluminum oxide which establishes an ideal bond with the base material. The surface of aluminum withstands multiple forms of damage because this integrated protective layer makes damage that harms untreated or painted surfaces impossible. The finish shows excellent longevity and structural resilience and extends product life expectancy because of heavy usage in public spaces or product handling applications thus making it a cost-effective choice with its higher initial pricing compared to competitive coatings.

2.Sleek Aesthetics That Never Go Out Of Style

Almost every design concept is enhanced by the classic beauty of the rich, deep black finish that anodizing produces. Anodized black creates a refined matte appearance with incredible depth, unlike paint, which is applied on top of the metal. Because of its subtle elegance, black anodized aluminum is now widely used in luxury consumer items, contemporary architecture, and high-end technology. Designers like this finish’s ability to subtly enhance other components in their works or create a striking statement. Because of its adaptability, black can be used with almost any color scheme or material, from chilly glass to warm woods, making it a timeless option that goes beyond fads.

3.Weather Resistance For Outdoor Applications

In demanding outdoor settings where other materials could soon degrade, black anodized aluminum performs exceptionally well. Through electrochemical processing metal surfaces acquire both moisture protection and resistance to corrosion as well as UV stability which defines its usage for outdoor installations. This method produces ideal results for outdoor furniture alongside signs and recreational equipment and outside architectural features because of its strong weather resistance properties. The anodic protection maintains its quality and appearance throughout many years without suffering paint deterioration from rain and sunlight exposure. The material proves most beneficial for coastal zones and extreme weather regions because it maintains its strength until replacement needs become absolutely necessary for outdoor components.

4.Environmentally Conscious Manufacturing Process

In today’s environmentally concerned market, the anodizing technique stands out as a comparatively eco-friendly metal finishing choice when compared to several alternatives. Anodized aluminum reduces hazardous emissions because it mainly uses water-based solutions instead of volatile organic chemicals which commonly appear in many paints and coatings. Anodized aluminum supports the circular economy because its complete recyclability occurs independently from finish separation from base material operations. Over time, less resources will be used and fewer replacements will be necessary due to the finish’s extraordinary longevity. Black anodized aluminum is a desirable choice for green construction projects and sustainability-focused product designs as modern anodizing plants frequently utilize closed-loop water systems and energy recovery procedures to further reduce their environmental effect.

5.Thermal Management Excellence

The outstanding heat dissipation properties of black anodized aluminum make it necessary for situations requiring temperature control. The protective outer coating produced by anodizing does not significantly affect aluminum’s natural ability to transmit and emit heat. The bright anodized aluminum shows high thermal efficiency which makes it suitable for electronic parts and automotive parts and lighting fixtures that prevent heat buildup that wears out their durability. The dark color of this finishing elevates the emission rate of heat energy instead of reducing it. Engineers appreciate the ability to combine heat transfer efficiency with industrial safety features through black anodized aluminum due to its applications in developing powerful small gadgets. The benefit extends product reliability and component durability together with design flexibility because temperature control obstacles cease to exist.

6.Electrical Insulation Benefits

Although aluminum conducts electricity well on its own, the anodized coating adds useful electrical insulating qualities that increase the material’s potential uses. Black anodized aluminum is appropriate for parts where electrical isolation is required in addition to conductive elements because the aluminum oxide layer formed during anodizing may tolerate high voltages before degrading. In electronic housings, electrical panel components, and specialized machinery, this dual nature—conductive base with insulating surface—proves very advantageous. During production, the anodic layer’s thickness may be adjusted to meet particular insulation needs while preserving the material’s other advantageous qualities. Aluminum’s exceptional heat conductivity and electrical resistance combine to provide a special material profile that addresses difficult design issues in contemporary electrical and electronic applications.

7.Lightweight Strength For Efficiency

Black anodized aluminum stands out through its strong weight ratio which delivers major advantages in applications that require durable structures and reduced weight. Anodized aluminum performs stronger than steel by weight yet remains lighter than aluminum does when used by itself according to most applications without adding additional mass. Black anodized aluminum excels in transportation applications that require fuel-efficient components because both strength and reduced weight are strongly connected. The material enables lighter, thinner, yet still robust designs in portable consumer goods. Black anodized aluminum delivers constructive benefits to projects through reduced shipping expenditures and minimal structural weight and easy handling capabilities. The main strength of black anodized aluminum stems from its exceptional durability with its lightweight properties.

Conclusion

Black anodized aluminum via Jm Aluminium stands superior to most other materials when combining its elegant external appearance with its beneficial performance properties. Black anodized aluminum operates effectively in many settings including electronics devices and buildings because of its performance capabilities along with durability and visual flexibility. The ability to extend service lifetime and recycle makes black anodized aluminum a leading sustainable material selection as companies advance their standards beyond performance to sustainability. Consider the special advantages of black anodized aluminum during the development of high-tech electric devices or modern architectural pieces as well as high-end equipment that functions in harsh conditions.